Gauges

Receiver Gauges | Special Gauges for GD &T and Dimension Checking|Functional Gauge

Receiver Gauges Function and application - when a part is manufactured, it must be measured to ascertain that it is of the right dimensions for fulfilling the purpose for which it is intended. Gauges are one of the commonly used inspection tools in production shops for quick checking and validation of the dimensions of manufactured parts. Thus, Gauging has become an integral part of any machining process and Gauges help in ensuring required degree of inter-changeability among the millions of parts manufactured worldwide. The type and the design of Gauges depend on the application, volume of production and precision levels required.

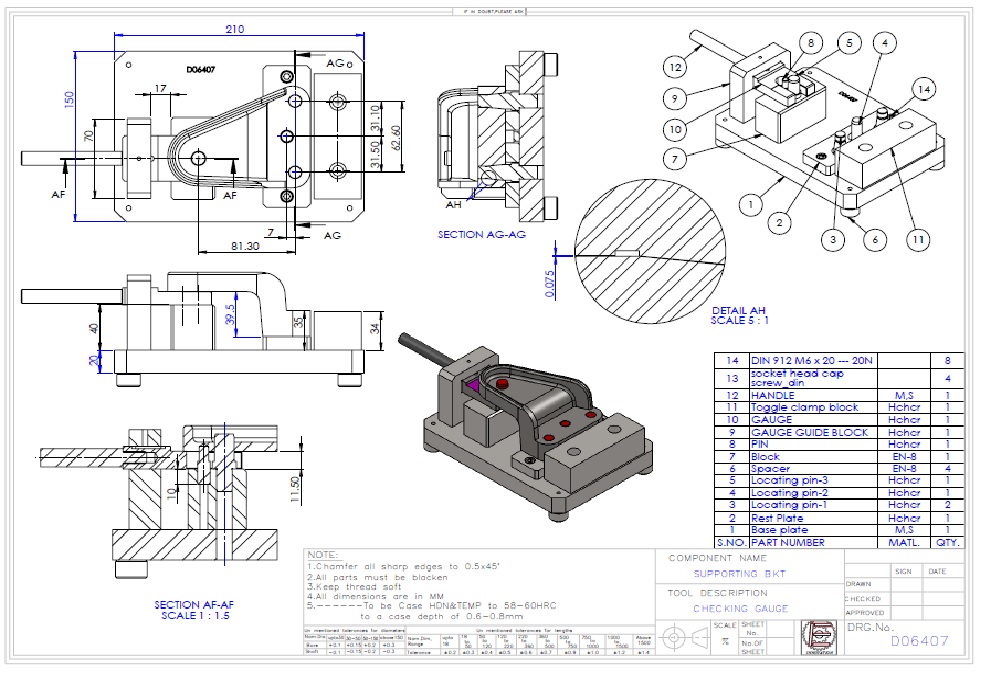

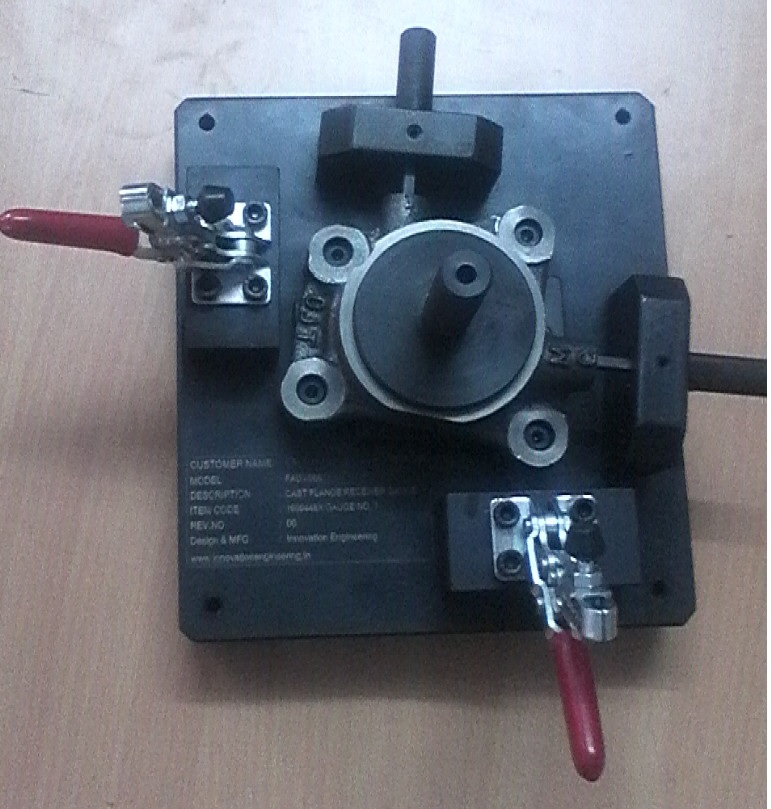

In addition to simple Plug and Ring Gauges, Functional Gauges or Receiver Gauges are being used to check location of different features with respect to the datum reference frame, as required. Functional Gauges are a very effective way to gauge products during or after manufacturing and they ensure trouble free assembly and operation. In all the cases, design of Gauges is of prime importance because, The considerations for Gauge design include part tolerances, Gauge material, simplicity of use, manufacturability, etc.

Gauges suggest and manufacturing under solution provided in-depth understanding of the types of Gauges requirements, principles of Gauge design, design criteria. It also gave them the guidelines for fixing tolerances for design of Gauges, selection of Gauge materials, design of Limit Plug and Gap Gauges, design of Functional Gauges for checking the positional tolerances with M Modifier, design of Gauges to check angular features, etc

Gauges Advantages

1. Fast functional inspection

2. Represents the actual interface

3. Gauges the virtual boundary

4. Easy to Use

5. Will not accept bad product